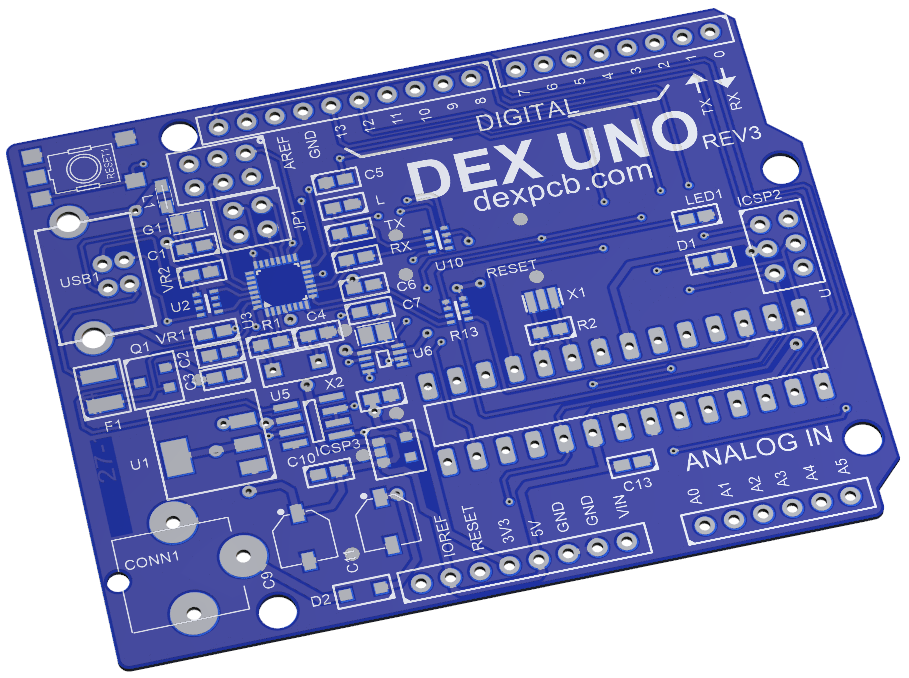

The PCB is the physical manifestation of your design and represents your ultimate goal - To make a PCB.

A Typical PCB with no Parts

A Printed Circuit Board (PCB) is a flat board made of insulating material that serves as the foundation for connecting electronic components. It mechanically supports and electrically connects various electronic components through conductive pathways, or traces, etched from copper sheets. PCBs are a fundamental part of nearly all electronic devices, from simple gadgets to complex systems like computers and smartphones.

Key Components of a PCB

•Substrate: The base material, often made of fiberglass or composite epoxy, provides structural support. The most common substrate material is FR-4.

•Copper Layer: A layer of copper is laminated onto the substrate to form conductive traces that connect different components on the PCB.

•Solder Mask: A protective layer applied over the copper traces to prevent short circuits and corrosion. It typically comes in green, but other colors are also available.

•Silkscreen Layer: This layer is used for printing labels, symbols, and other markings on the PCB for identification and assembly purposes.

•Pads: These are small areas where electronic components are soldered onto the PCB. They provide the electrical connection points for components like resistors, capacitors, and integrated circuits.

•Vias: These are small holes that allow electrical connections between different layers of a multilayer PCB. They are crucial for routing signals from one layer to another.

Types of PCBs

•Single-Sided PCBs: These have components mounted on one side and traces on the other. They are simple and cost-effective, commonly used in basic electronic devices.

•Double-Sided PCBs: These have conductive traces on both sides of the board, allowing for more complex designs and a greater number of components. They are connected by vias.

•Multilayer PCBs: These consist of multiple layers of substrate and copper, allowing for very complex circuitry in compact spaces. They are used in advanced applications, such as computers and smartphones.

•Flexible PCBs: Made from flexible materials, these PCBs can bend and twist, making them suitable for applications where space is limited or in wearable devices.

•Rigid-Flex PCBs: These combine rigid and flexible PCB technology, allowing for intricate designs that can flex in certain areas while remaining rigid in others.

Applications of PCBs

•Consumer Electronics: Used in devices like smartphones, tablets, televisions, and computers.

•Automotive: Integrated into vehicle systems for control, navigation, and entertainment.

•Medical Devices: Found in diagnostic equipment, monitoring systems, and therapeutic devices.

•Industrial Equipment: Used in machinery control systems and automation.

•Telecommunications: Essential for network equipment, routers, and communication devices.

Manufacturing Process

•Design: Using PCB design software, engineers create the layout, specifying components, traces, and other features.

•Fabrication: The board is manufactured by etching the copper layer to form the desired circuit pattern and applying solder mask and silkscreen layers.

•Assembly: Components are mounted onto the PCB using soldering techniques such as wave soldering or surface-mount technology (SMT).

•Testing: After assembly, the PCBs are tested for functionality and reliability before being integrated into final products.

Advantages of PCBs

•Compact Design: PCBs allow for high-density circuit designs, saving space in electronic devices.

•Cost-Effectiveness: Mass production of PCBs reduces manufacturing costs, making them affordable for a wide range of applications.

•Reliability: PCBs are robust and can withstand environmental factors, leading to longer lifespans for electronic devices.

•Ease of Production: Standardized manufacturing processes streamline production and assembly.

Summary

A PCB is a crucial component in modern electronics, providing the structural and electrical framework for connecting components. Its design and manufacturing processes play a significant role in the functionality, reliability, and performance of electronic devices across various industries.